The mold build designed to shorten time-to-market and reduce tooling costs.

Have you ever approached an injection molder looking to source a quote for a project still in the development phase? If so, you might have balked at the initial tooling price. Why on Earth would you invest so much upfront on a project you’re not sure will succeed on the market?

Well, there’s another tooling option that you might not be aware of – MUD units. In a nutshell, a MUD unit is capable of making quality, precision parts without the price tag. This is the perfect tool build to produce a short run for your engineering or market tests.

In this article, we’ll go into more detail about what a MUD unit is and how it works. You’ll also find the benefits of this type of build and its capabilities. Finally, we’ll send you home with some notes to take back to your engineering team. If you have further questions, please reach out!

What is a MUD Mold Base?

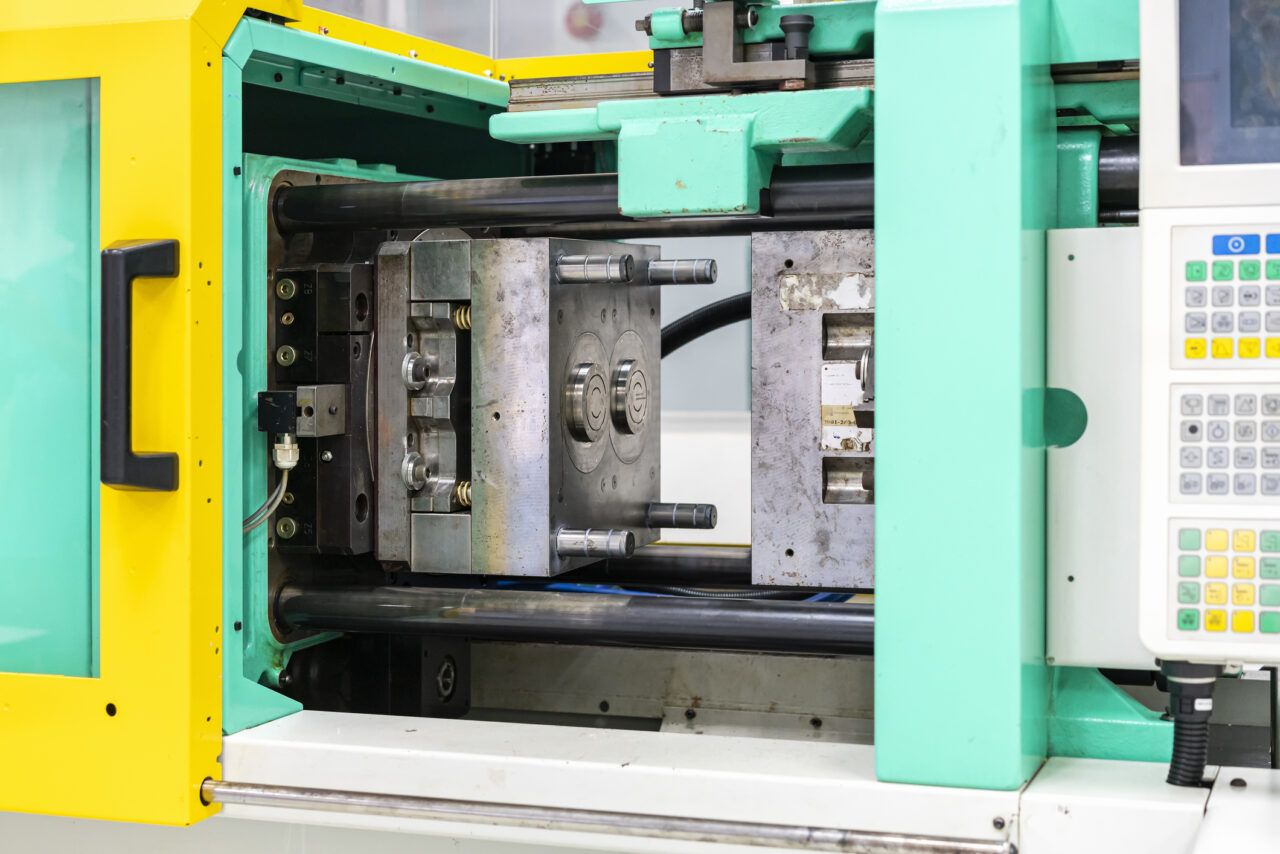

A MUD – or Master Unit Die – is a modular mold base that houses interchangeable cavity and core inserts. These builds use a standard-size mold frame that can be left in an injection molding machine while a mold technician completes a changeover. In other words, the molder can change molds by simply removing the core and cavity inserts and replacing them with another compatible set. This is ideal when you have multiple product configurations or a product still in development.

What Does a MUD Base Do?

MUD bases are a cost-effective, yet productive alternative to full-sized molds (full chase). The modular nature of a MUD unit allows molders to quickly switch mold configurations or even to other products with minimal downtime. Once the mold frame is in place, the molder can quickly change out the core and cavity inserts in favor of a different set. In just a few steps, the manufacturer can go from molding one product to another.

Choosing a mold base will still allow you to build *thousands of parts with quality and precision. In fact, the ability of these tools is on par with small and medium-run injection molding tools. Furthermore, many mold builders can build these while incorporating hot runners and other mold accessories to drive better manufacturing results.

MUD Bases and Project Development

It is true – MUD bases are perfect for projects that are still in development or going through design changes.

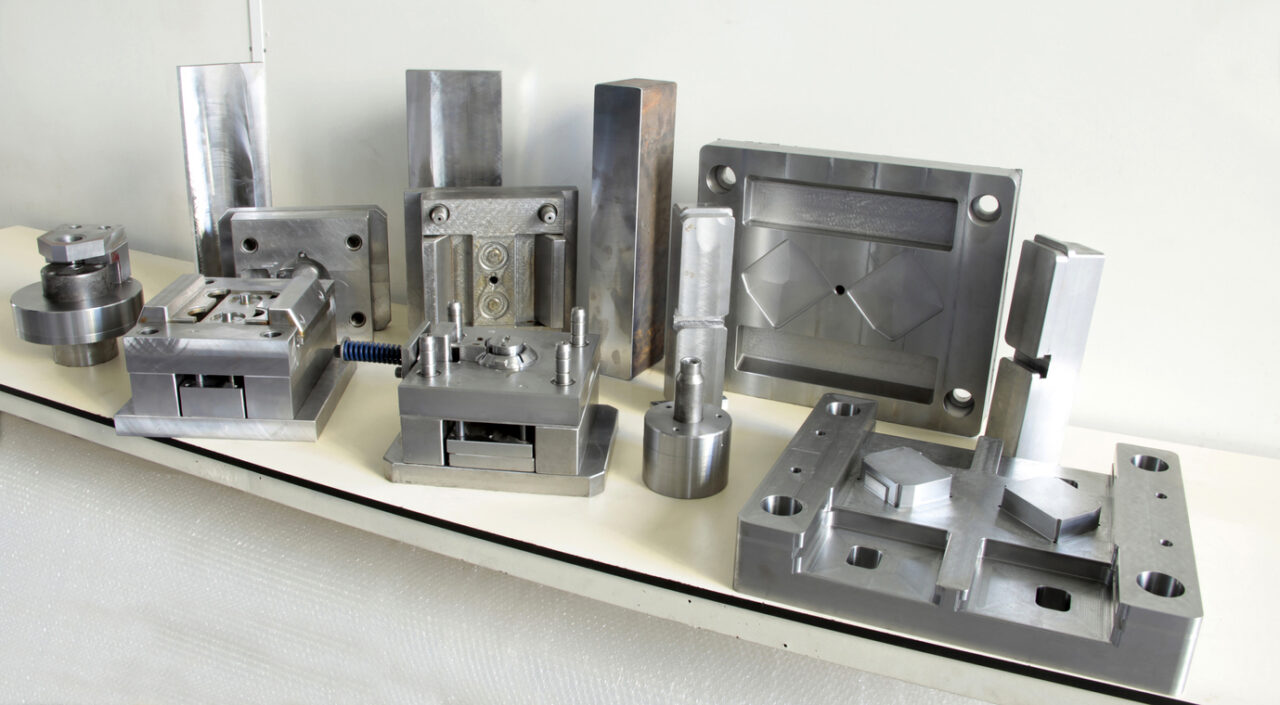

Having removable inserts makes troubleshooting and making tooling adjustments much easier. This is mainly due to the technician not having to remove an entire mold base. In addition, the mold builder can work quicker by not having to disassemble multiple mold plates.

These inserts are typically made of P20 or H13 steel. The former is softer and therefore easier to machine. This makes modifying the tool to address a design change much more feasible. However, drastic changes to a design may require building new inserts completely.

Ultimately, this is better than having to build an entirely new mold.

Benefits of MUD Bases

We’ve covered a few of the benefits of MUD bases already. Here is a summary of those benefits:

· Setup time reduced from hours to minutes

· Quick/ easy to modify without removing an entire mold frame

· Minimal production downtime

· Easy to handle, use, install, and maintain

· Lower tooling build cost as you only need to purchase in A& B inserts and not the entire mold base.

· Lower molding processing costs from quick mold change reducing downtime

· Lower labor costs by reducing the number of techs working on one mold.

· Speed to market is improved by reducing machining time and workload.

· Sustainability – the frame can be reused with other inserts.

· Supply chain flexibility to support just-in-time scheduling

Types of MUD Bases and Frames

As we discussed, the core and cavity inserts have a ton of customization options. Mold frames on the other hand do not.

Mold frames are more standardized in size and build. For the inserts to have a proper fit and truly be modular– you need the proper frame shape. Fortunately, there are a handful of shapes available that allow you to be more flexible with your insert configurations.

Here are a few of the main ones:

U-frame: standard single insert

H-frame: standard double insert

Double H-frame: Standard 4 insert

E-Frame: side by side double insert

What You Do and Don’t Need to Know (Conclusion)

It is unlikely that you will have to decide for yourself which mold frame to go with. Your injection molder will have the insight to use the best frame for your MUD unit.

On the other hand, it is up to you to understand the capabilities and limitations of the MUD unit. While it is possible to have a MUD unit produce hundreds of thousands of parts – that is beyond its life expectancy. Furthermore, you should expect to see wear on the tool where there are moving parts (slides, cores, pins, etc.). This can cause issues with production and impact the final part quality or result in unplanned downtime.

Therefore, you should have a conversation with your molding partner to see if building a high-volume production tool is right for your project. At that point, you can plan an appropriate timeline for ramping up production and minimizing potential downtime.

Launching a new product soon?

If you’re planning to launch a project in the next year and need a MUD unit for market testing – we can get one built for you! Visit our website and fill out an RFQ form to start the process. We look forward to working with you!