Custom Injection Molding Solutions for Electronic Components

Mold Parts With Speed, Consistency, and Quality

Consider Plastics Plus Technology for

your next molding project. With

a wide array of molding capabilities, proven processes and excellent customer

service, you will receive high quality parts on time, when you need them. Let us be your trusted partner for electronic injection molded parts and assemblies.

Learn More About Our ServicesSub TextSpeak With An EngineerSub Text

Custom Injection Molding Solutions for Electronic Components

Thermoplastic electronic components are essential to today’s technology-filled world. From electronic housings to electrical relays, plastic helps facilitate the use of many modern devices. With the right material, these electronic components can benefit from non-corrosive, electricity dissipating, and naturally insulating qualities. This is important for keeping the assembly and the user safe.

As for injection molding- OEM’s of high-powered electronic equipment can utilize this manufacturing process in a number of different ways. For example, with custom molding your parts are made custom to your specifications. Tight-tolerance, material compatibility, and versatility are all sought out by electronics manufacturers. Ultimately, you’ll find that Plastics Plus has everything you need for your high-volume production needs.

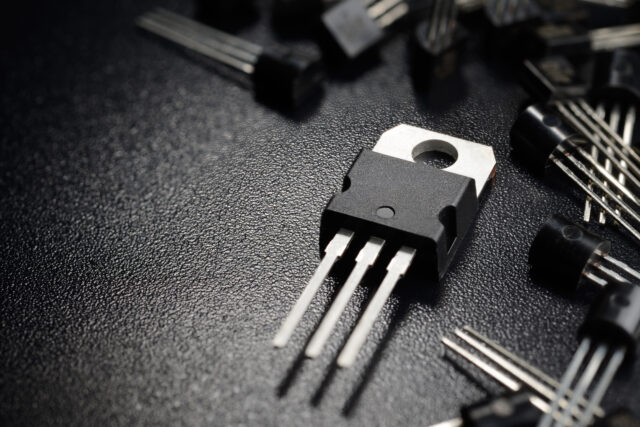

Transistors – Example Part

Reduce Costs with Lean Manufacturing and Assembly Operations

Whether your product is a single, standalone part that needs packaging, or if it is a complex multi-component assembly, we have the capabilities you need to assemble your product. Our production facility is well equipped to handle a variety of value added operations to move your project through the production process. From hands-on assembly to automated packaging, we will handle your project with care.

Need More Reasons To Let Us Assemble Your Product?

Take advantage of Lean Manufacturing practices Speed up cycle times with efficient assembly and packagingAutomated packaging for consistent resultsReduce cost of labor and facility spaceScale production to match customer demand

Industry Standard Quality Assurance

ISO 13486:2016 + ISO 9001:2015

This ISO certification is the primary quality management standard for medical devices in the US. This standard ensures that our quality systems is effective implemented and maintained. PPT utilizes this to continuously improve our end-to-end processes, ensuring that the medical components meet your expectations.

Good Manufacturing Practices

Plastics Plus is compliant with all CGMPS as required by the FDA’s 21 CFR. This includes requirements related to methods used in, and the facilities and controls used for: designing, manufacturing, packaging, labeling, storing, installing, and the servicing of medical devices for human use.

Want More Supplier Transparency?

Discover why Plastics Plus Technology is renown for being a trusted partner among medical component manufacturers!

Clear Communication

Nobody wants to run around looking for the answers to their questions. That’s why we provide you with the information you need when you need it. No-nonsense business you would expect from your business partner.

Material Expertise

As a custom molder we have a deep history of working with a number of different materials. You can be sure that we have the capabilities to work with your specified material, or we can even suggest one for you!

Maximize Supply-Chain Efficiency

We maximize our customers supply-chain efficiency by offering unique post-production services such as: insert molding, over molding, assembly, ultra-sonic welding, packaging and more!

Discover Why Our Partnership Counts

Setup your next molding project for success with a quality partnership

Design Recommendations

Prepare your project for success with expert tooling and production advice from our engineering team.

Build a Trustworthy Partnership

Our customer’s success is at the core of our company’s focus. Eliminate friction in your supplier network and join a trustworthy partnership today.

USA Manufacturing

End-to-end processes: from mold builds to processing and shipping, all done from the United States. Reap the benefits of a domestic partnership that simplifies your supply-chain.

Diligent Quality Assurance

We never sell our customers short on quality. Make sure the quality of your parts stay a top priority with Plastics Plus.

Ready to Make Quality Electronic Components?

© Copyright Plastics Plus Technology, Inc 2021. Built with OptimizePress.

- Menu

- About Us

- Social Media

- Contact Us

Under construction. Check back later

Plastics Plus Technology is a woman-owned, USA contract manufacturer based in sunny Southern California. Our custom injection molding and value-added services can provide you with a one-stop job shop for all your injection molding needs.

ISO 9001:2015, ISO 13485:2016 Certified. FDA Registered. Good Manufacturing Practices (GMPs). WBENC.